Basic classification of rubber joints: General class: The general category of rubber expansion joints is suitable for various applications such as conveying water within a temperature range of -15℃ to 80℃. They can also handle acid solutions or alkali solutions with a concentration of less than 10%. These expansion joints provide flexibility and reliability in common industrial settings. Special category: The special category of rubber expansion joints is designed for specific performance requirements. For example, there are expansion joints that offer oil resistance, making them ideal for applications involving oil or petroleum-based fluids. Some expansion joints are resistant to plugging, which is useful in situations where blockages or debris may be present. There are also expansion joints with ozone resistance, wear resistance, or chemical corrosion resistance, enabling them to withstand harsh environments or corrosive substances. Heat-resistant type: Heat-resistant rubber expansion joints are specifically designed to handle higher temperatures. They are suitable for conveying water with a temperature exceeding 80℃. These expansion joints are typically made of materials that can withstand elevated temperatures and maintain their structural integrity.1.Structure types: Rubber expansion joints come in various structures to accommodate different piping system requirements. The different forms include: 2.Single sphere: This structure consists of a single spherical shape that allows for axial, lateral, and angular movements. 3.Double sphere: Double sphere expansion joints have two spherical shapes that offer increased flexibility and absorption of movement. 4.Three sphere: Three sphere expansion joints feature three spherical shapes, providing even greater flexibility and movement compensation. 5.Elbow sphere: Elbow sphere expansion joints are specially designed to accommodate movements in piping systems with bends or elbows. 6.Wind pressure coil body: This structure is used for applications where the expansion joint needs to withstand wind pressure or external forces.

Basic classification of rubber joints: General class: The general category of rubber expansion joints is suitable for various applications such as conveying water within a temperature range of -15℃ to 80℃. They can also handle acid solutions or alkali solutions with a concentration of less than 10%. These expansion joints provide flexibility and reliability in common industrial settings. Special category: The special category of rubber expansion joints is designed for specific performance requirements. For example, there are expansion joints that offer oil resistance, making them ideal for applications involving oil or petroleum-based fluids. Some expansion joints are resistant to plugging, which is useful in situations where blockages or debris may be present. There are also expansion joints with ozone resistance, wear resistance, or chemical corrosion resistance, enabling them to withstand harsh environments or corrosive substances. Heat-resistant type: Heat-resistant rubber expansion joints are specifically designed to handle higher temperatures. They are suitable for conveying water with a temperature exceeding 80℃. These expansion joints are typically made of materials that can withstand elevated temperatures and maintain their structural integrity.1.Structure types: Rubber expansion joints come in various structures to accommodate different piping system requirements. The different forms include: 2.Single sphere: This structure consists of a single spherical shape that allows for axial, lateral, and angular movements. 3.Double sphere: Double sphere expansion joints have two spherical shapes that offer increased flexibility and absorption of movement. 4.Three sphere: Three sphere expansion joints feature three spherical shapes, providing even greater flexibility and movement compensation. 5.Elbow sphere: Elbow sphere expansion joints are specially designed to accommodate movements in piping systems with bends or elbows. 6.Wind pressure coil body: This structure is used for applications where the expansion joint needs to withstand wind pressure or external forces.Clamp type rubber soft joint

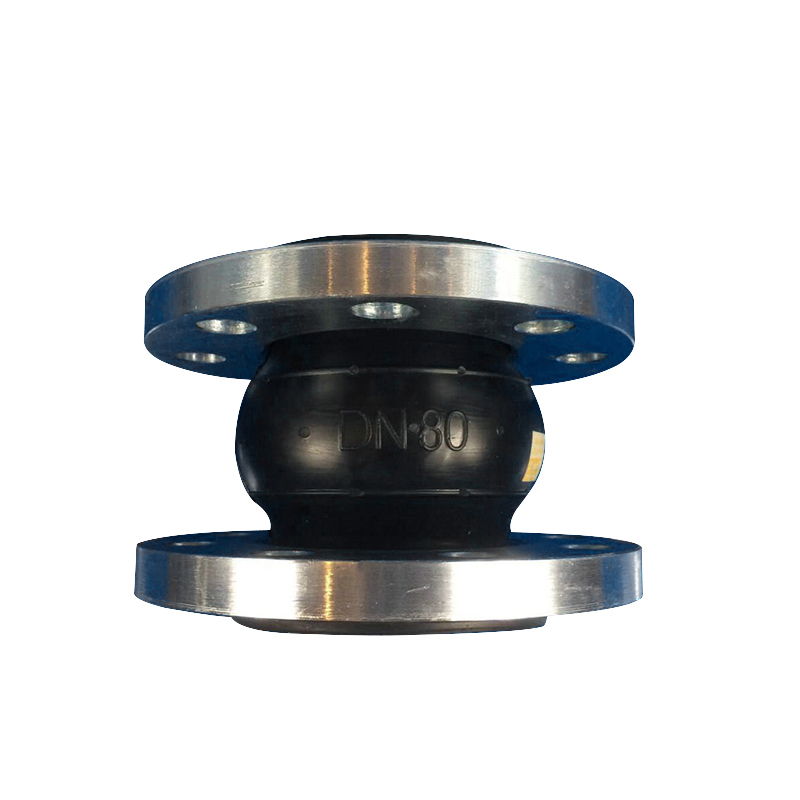

Get high-quality clamp type rubber soft joint from our factory. Durable, reliable, and made to last. Order yours today!

Request a QuotePRODUCTS DETAILS

Basic classification of rubber joints: General class: The general category of rubber expansion joints is suitable for various applications such as conveying water within a temperature range of -15℃ to 80℃. They can also handle acid solutions or alkali solutions with a concentration of less than 10%. These expansion joints provide flexibility and reliability in common industrial settings. Special category: The special category of rubber expansion joints is designed for specific performance requirements. For example, there are expansion joints that offer oil resistance, making them ideal for applications involving oil or petroleum-based fluids. Some expansion joints are resistant to plugging, which is useful in situations where blockages or debris may be present. There are also expansion joints with ozone resistance, wear resistance, or chemical corrosion resistance, enabling them to withstand harsh environments or corrosive substances. Heat-resistant type: Heat-resistant rubber expansion joints are specifically designed to handle higher temperatures. They are suitable for conveying water with a temperature exceeding 80℃. These expansion joints are typically made of materials that can withstand elevated temperatures and maintain their structural integrity.1.Structure types: Rubber expansion joints come in various structures to accommodate different piping system requirements. The different forms include: 2.Single sphere: This structure consists of a single spherical shape that allows for axial, lateral, and angular movements. 3.Double sphere: Double sphere expansion joints have two spherical shapes that offer increased flexibility and absorption of movement. 4.Three sphere: Three sphere expansion joints feature three spherical shapes, providing even greater flexibility and movement compensation. 5.Elbow sphere: Elbow sphere expansion joints are specially designed to accommodate movements in piping systems with bends or elbows. 6.Wind pressure coil body: This structure is used for applications where the expansion joint needs to withstand wind pressure or external forces.

Basic classification of rubber joints: General class: The general category of rubber expansion joints is suitable for various applications such as conveying water within a temperature range of -15℃ to 80℃. They can also handle acid solutions or alkali solutions with a concentration of less than 10%. These expansion joints provide flexibility and reliability in common industrial settings. Special category: The special category of rubber expansion joints is designed for specific performance requirements. For example, there are expansion joints that offer oil resistance, making them ideal for applications involving oil or petroleum-based fluids. Some expansion joints are resistant to plugging, which is useful in situations where blockages or debris may be present. There are also expansion joints with ozone resistance, wear resistance, or chemical corrosion resistance, enabling them to withstand harsh environments or corrosive substances. Heat-resistant type: Heat-resistant rubber expansion joints are specifically designed to handle higher temperatures. They are suitable for conveying water with a temperature exceeding 80℃. These expansion joints are typically made of materials that can withstand elevated temperatures and maintain their structural integrity.1.Structure types: Rubber expansion joints come in various structures to accommodate different piping system requirements. The different forms include: 2.Single sphere: This structure consists of a single spherical shape that allows for axial, lateral, and angular movements. 3.Double sphere: Double sphere expansion joints have two spherical shapes that offer increased flexibility and absorption of movement. 4.Three sphere: Three sphere expansion joints feature three spherical shapes, providing even greater flexibility and movement compensation. 5.Elbow sphere: Elbow sphere expansion joints are specially designed to accommodate movements in piping systems with bends or elbows. 6.Wind pressure coil body: This structure is used for applications where the expansion joint needs to withstand wind pressure or external forces.Hot Products

Malleable iron Pipe Fitting Union

Clamp type rubber soft joint

Gi Iron Pipe Thread Flange

Malleable iron Pipe Fitting Beaded 90 Degree Elbow

Malleable iron Pipe Fitting Banded Tee

Malleable iron Pipe Fitting Banded 90 Degree Elbow

Elbow Type Rubber soft joint

Single ball rubber soft joint

Thread-connection rubber joint

Malleable iron Pipe Fitting Hexagon Nipple

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours